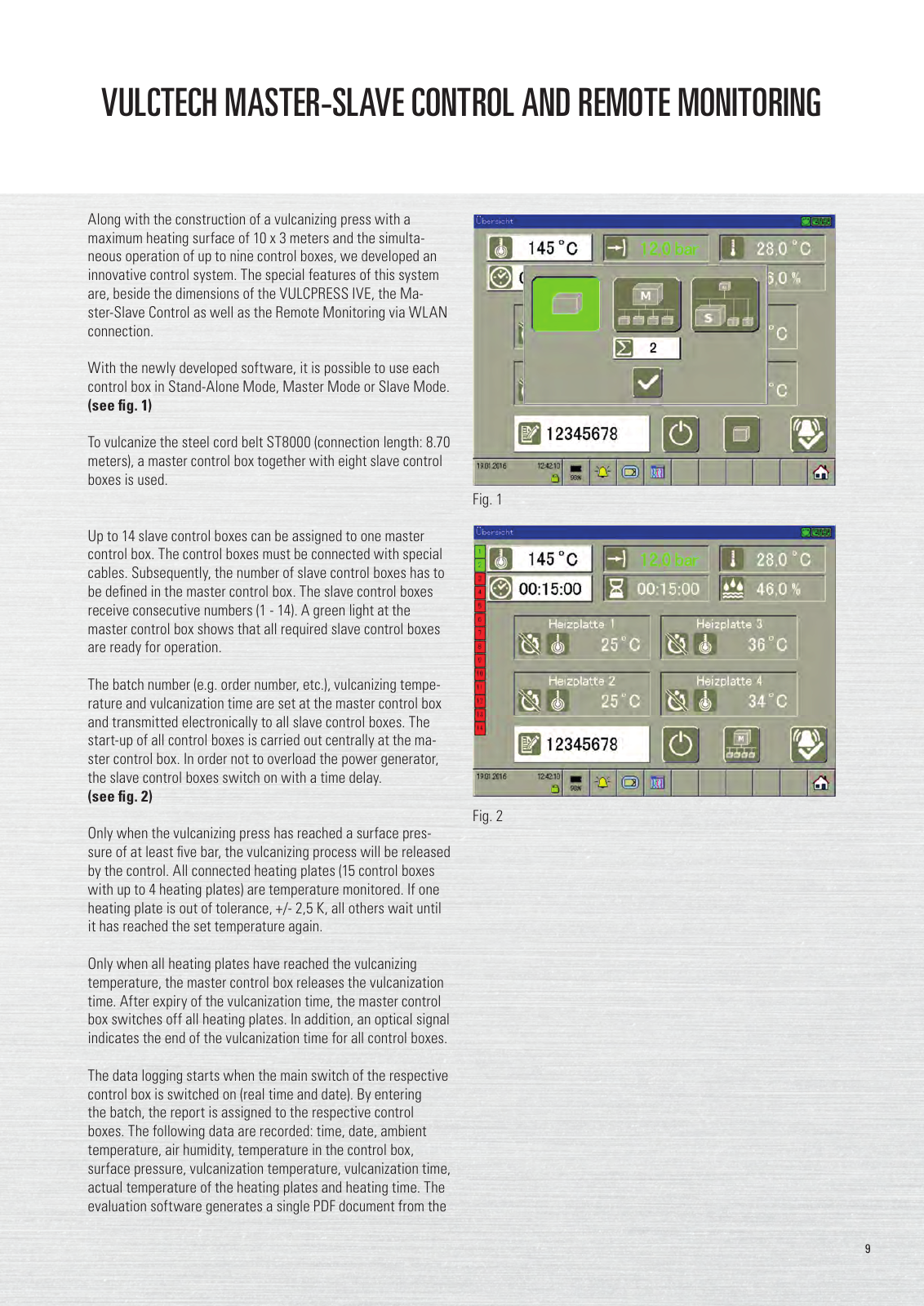

9 VULCTECH MASTER SLAVE CONTROL AND REMOTE MONITORING Along with the construction of a vulcanizing press with a maximum heating surface of 10 x 3 meters and the simulta neous operation of up to nine control boxes we developed an innovative control system The special features of this system are beside the dimensions of the VULCPRESS IVE the Ma ster Slave Control as well as the Remote Monitoring via WLAN connection With the newly developed software it is possible to use each control box in Stand Alone Mode Master Mode or Slave Mode see fig 1 To vulcanize the steel cord belt ST8000 connection length 8 70 meters a master control box together with eight slave control boxes is used Up to 14 slave control boxes can be assigned to one master control box The control boxes must be connected with special cables Subsequently the number of slave control boxes has to be defined in the master control box The slave control boxes receive consecutive numbers 1 14 A green light at the master control box shows that all required slave control boxes are ready for operation The batch number e g order number etc vulcanizing tempe rature and vulcanization time are set at the master control box and transmitted electronically to all slave control boxes The start up of all control boxes is carried out centrally at the ma ster control box In order not to overload the power generator the slave control boxes switch on with a time delay see fig 2 Only when the vulcanizing press has reached a surface pres sure of at least five bar the vulcanizing process will be released by the control All connected heating plates 15 control boxes with up to 4 heating plates are temperature monitored If one heating plate is out of tolerance 2 5 K all others wait until it has reached the set temperature again Only when all heating plates have reached the vulcanizing temperature the master control box releases the vulcanization time After expiry of the vulcanization time the master control box switches off all heating plates In addition an optical signal indicates the end of the vulcanization time for all control boxes The data logging starts when the main switch of the respective control box is switched on real time and date By entering the batch the report is assigned to the respective control boxes The following data are recorded time date ambient temperature air humidity temperature in the control box surface pressure vulcanization temperature vulcanization time actual temperature of the heating plates and heating time The evaluation software generates a single PDF document from the Fig 1 Fig 2

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.